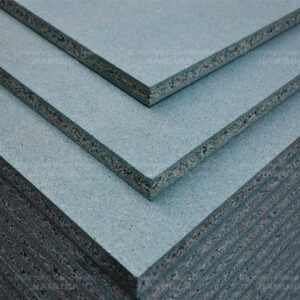

Particle board-also known as chipboard and flake board, is an engineered wood product manufactured from wood chips, sawmill shavings, or even sawdust, and a synthetic resin or other suitable adhesive which is pressed by machinery with high pressure and high temperatures.

The advantages of particle board:

Its cost is very low over solid wood or plywood

Light weight makes it relatively easy to transport and move around

The conversion time is much less as compared to post lamination

Particle board is widely used for making furniture, interior works, making wall partitions, counter tops,cabinets, sound insulation (for speaker box) and flush doors core etc…

Specifications of Plain Particle Board

| Name | Particle Board(Chipboard) |

| Material | Poplar Or Pine Fiber |

| Moisture | 4-12% |

| Thickness | 2mm-40mm |

| Size | 1220X2440mm(4’x8′), 915x2135mm(3’x7′) |

| Glue | E1,E2 |

| Density | ≥750kg/M3 |

| Usage | 2mm-40mm Use In Furniture |

| Packing | Bulk Packing Or Standard Pallet Packing |

| Certification | SGS, FSC |

Quality features

1. The perfect rigidity, flatness and smoothness of our board ensure a strong, stable and beautiful end product.

2. Thanks to the dimensional stability of our board, products remain flat and stable in different climates.

3. The flatness of our board, combined with constant calipers and sizes, ensures excellent running on processing machinery.

4. The board surface has the right absorption capacity to allow quick and economic gluing.

5. Our board is easy to rotary cut, die cut, punch, crease, score, drill and rout.