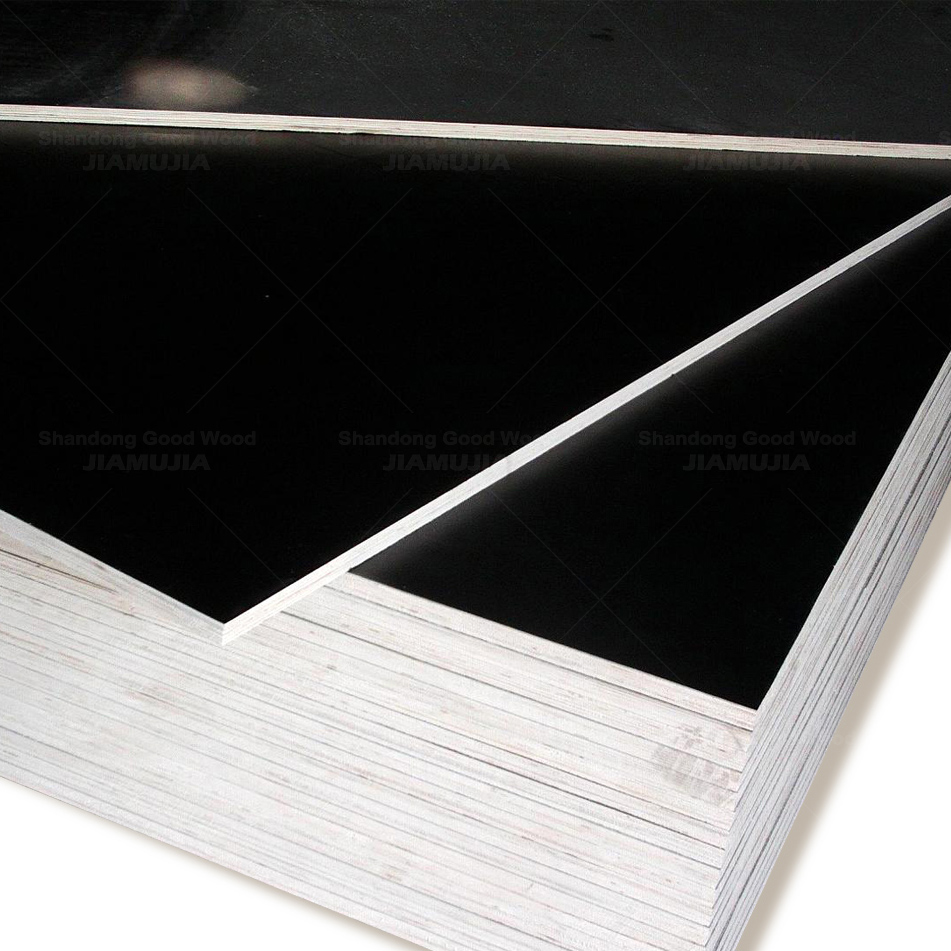

Film faced plywood is widely used in construction and building and vehicle industry. Film faced plywood is very resistant to water, easy to clean and cut.

Well sorted out veneers laid up with alternate grain direction, glued up together with 100% water boiling proof Phenolic and Melamine resin and pressed under a temperature no less than 140C and specific pressure of 12kg/cm2. In a second operation high quality black film is laid on the basic panel whose edges are then paint –sealed with 100% water proof paint in order to provide the utmost water resistance performance to the product.

| Face/Back: | Black Film, Brown Film, Anti slip film |

| Core: | Birch, Hardwood, Poplar, etc |

| Standard sizes(mm): | 1220×2440, 1250×2500, 920×920, 915×1830, 1200×1800.

Customized size are available. |

| Standard thickness(mm): | 4, 6, 9, 12, 15, 18, 21, 24, 27, 30. |

| Glue: | WBP Phenolic; Melamine |

| Moisture content(%): | 5-14 |

| Density (kg/m3): | 520-700 |

| Thickness Tolerance(mm): | +/- 0.5mm |

| Length or Width Tolerance(mm): | +/- 2mm |

| Number of Plies: | From 5 up to 21 depending on thickness |

| Edges Processing: | By waterproof acrylic paint |

| Application: | Can be widely used for outdoor construction |

| Package: | Standard export packing |